Two leading solutions for fruit and vegetable packaging will be the focus of GNA's first participation as an exhibitor at Fruit Attraction. The company, based in the heart of the Emilia packaging valley near Bologna, specialises in the design, manufacture, and sale of packaging machines for food and non-food products.

In Madrid, GNA will showcase Sewellia, the compact and efficient automatic heat sealer, and the Wrap Box 600 cover applicator, confirming its commitment to offering flexible, high-performance, and sustainability-oriented technologies. Explaining the strategy is Gabriella Bolzoni, export sales, who emphasises how participation in Fruit Attraction represents "an opportunity to strengthen international visibility and open up to new markets, particularly emerging ones."

© Maria Luigia Brusco | FreshPlaza.com

© Maria Luigia Brusco | FreshPlaza.com

Gabriella Bolzoni visiting the FreshPlaza stand at Fruit Attraction 2024

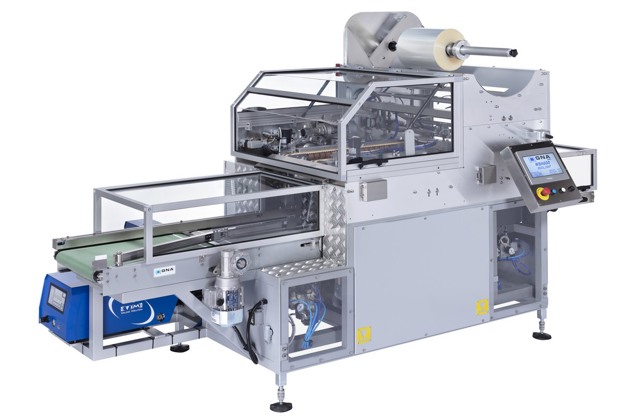

Sewellia is an automatic heat sealer designed for easy and efficient operation. "Compact and accessible from both sides, it is constructed entirely of stainless steel and is easy to sanitise, which is an increasingly important aspect for those working with fresh produce. The machine is also equipped with advanced protective devices that ensure the highest safety standards, while the user interface is made intuitive and straightforward by an integrated ten-inch panel. The LED-illuminated work area offers excellent visibility and contributes to smooth daily operations," explains Bolzoni.

From a technical point of view, Sewellia stands out for the possibility of rapid format change without the use of tools, thanks to a dedicated trolley, and for the presence of integrated remote assistance that guarantees intelligent connectivity and immediate support. "The machine is customisable and can work with either seal only or modified atmosphere. Sealing is done with a fully mechanical mould rise, while sealing and cutting are pneumatic, a solution that ensures efficiency and reliability. The drive of the unwinder and the infeed and outfeed belts is controlled by brushless motors, which guarantee precision and stability."

© G.N.A. SrlThe Sewellia automatic heat sealer from GNA

© G.N.A. SrlThe Sewellia automatic heat sealer from GNA

Performance is top class: Sewellia can reach a maximum speed of twenty cycles per minute in ambient atmosphere, packaging up to eighty trays per minute depending on the mould used. The maximum width of the film reel is 390 millimetres, while the maximum format that can be processed is 460 by 270 millimetres, with a product height between 15 and 120 millimetres. Consumption is low, with an electrical consumption of 4.5 kW and a compressed air requirement of NL 15 per minute.

"Application versatility is a further added value. Sewellia is, in fact, suitable for various food sectors, from convenience food to fresh and fresh-cut fruit and vegetables, to products such as pasta, rice, dairy products, meat, and fish. The focus on sustainable packaging is another central aspect: the machine can process both single-material and multilayer plastic trays and cardboard solutions, recyclable and biodegradable materials, thus responding to the new environmental requirements of the supply chain. The different packaging formats will be on display at the Madrid fair.

© G.N.A. Srl

© G.N.A. Srl

Alongside Sewellia, GNA will also showcase the Wrap Box 600 cover applicator. This is a solution developed to hot-apply a cover film onto cardboard or wooden trays of different formats, between 20x30 and 40x60 centimetres. The film, which can be micro- or macro-perforated, printed, or neutral, provides protection and visibility for the product. In addition to the most common flexible materials, such as compostable household materials or traditional plastic films, the machine can process innovative combinations such as extruded mesh with film or cotton mesh with paper. Thanks to this versatility, Wrap Box 600 is suitable for wrapping crates of different sizes and can be used on a wide range of fruit and vegetable products: from citrus fruits to stone fruits such as apricots, cherries, and peaches, to kiwis, apples, tomatoes, pears, and grapes.

GNA's Wrap Box 600 cover applicator

Automation - now a strategic necessity

"Customer demands are increasingly moving in the direction of solutions that reduce operating costs and compensate for the difficulty of finding labour. Staying competitive means focusing on technologies that can increase productivity and guarantee process continuity," Bolzoni emphasises.

The decision to take part in Fruit Attraction came after years of visits as mere observers. "We have always appreciated the fair's formula, which brings together producers and technology suppliers in the same pavilion. This year, it seemed like the right opportunity to present our machines to a wide and multicultural audience."

The main objective is to expand the international presence and build new business relationships. "Fruit Attraction gives us the opportunity to look at markets where we are not yet present and, at the same time, to consolidate existing relationships," Bolzoni concludes.

GNA will be exhibiting at Fruit Attraction 2025 (Madrid, 30 September-2 October) in Hall 10, Stand 10B27.

For more information GNA s.r.l.

GNA s.r.l.

Via Progresso, 15 - z.i. Ponte Rizzoli

40064 Ozzano dell'Emilia (BO) - Italy

Tel.: +39 051 799226

Fax: +39 051 796962

[email protected]

www.gnasrl.com