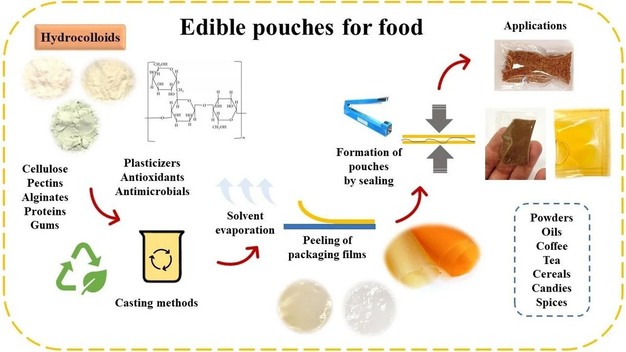

A recent review in Processes discusses advances in edible food packaging, focusing on single-use, fast-dissolving edible pouches as an alternative to plastics. Plastic packaging, widely used in food preservation, remains a major source of environmental waste, prompting research into biopolymer-based systems.

Edible coatings and films, produced from polysaccharides, lipids, or proteins, are regulated under European and U.S. food safety frameworks. They serve as barriers against gases and microbial contamination while maintaining shelf life. Examples include cellulose and starch films resistant to moisture, gelatin or whey protein films providing flexible strength, and waxes or fatty acids as water barriers.

© News-Medical.net

© News-Medical.net

The European Union's Green Deal and Regulation 1935/2004 support the use of such packaging to reduce reliance on non-biodegradable plastics and improve local waste management.

Edible films may be applied directly to food surfaces or preformed. Applications include sachets that absorb carbon dioxide, ethylene, or moisture to prevent spoilage and over-ripening. These systems can contribute to a circular economy, although the direct impact remains under review.

One highlighted format is fast-dissolving edible pouches for single servings of foods and beverages. Examples include whey protein isolate films for instant coffee, soybean polysaccharide and gelatin films for coconut powder, corn zein films for cheese, and gelatin/chitosan blends for shrimp oil. Such systems dissolve on contact with water and are being studied for powders, oils, and other dry products.

The review distinguishes between active and intelligent packaging. Active packaging controls the product environment by removing oxygen, moisture, or ethylene, or releasing antioxidants or preservatives, without direct food contact. Intelligent packaging integrates biosensors to monitor conditions such as pH, oxygen levels, carbon dioxide, or bacterial metabolites, transmitting data on food quality.

Edible packaging also provides dosing convenience, reduces packaging needs, and may lower the carbon footprint by limiting plastic waste. When made from byproducts of food processing, it can improve resource efficiency. Compostable systems are being tested, though many require controlled conditions for full breakdown.

Challenges remain in mechanical strength, moisture and oxygen barriers, regulatory approval, and consumer acceptance. Concerns include possible flavor changes and contamination, while the use of some synthetic additives, such as sulfites, raises health questions.

The review concludes that edible pouches and coatings could provide a scalable option for fresh and processed foods if technical and regulatory hurdles are addressed. Data-driven methods, nanotechnology, and encapsulation are identified as areas for further development.

Source: News Medical Life Sciences