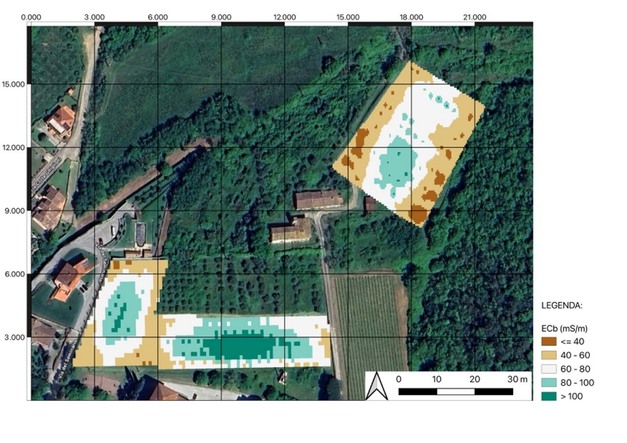

In the heart of Tuscany, nestled between the hills of Lucca and the coast of Bolgheri, are two companies: Cooperativa Calafata and Azienda Agricola Campo al Noce. Both are involved in the H2Coop project, which aims to transfer innovative technologies that facilitate orchard and vineyard irrigation management in cooperatives. The two companies have decided to install three 60-centimeter Sentek Drill & Drop probes. The installation areas were identified through electromagnetic induction (EMI) surveys, which mapped the soil's apparent electrical conductivity (ECa).

© Sentek Srl © Sentek Srl |  © Sentek Srl © Sentek Srl |

Apparent Electrical Conductivity Maps for the Calafata and Campo al Noce Vineyards

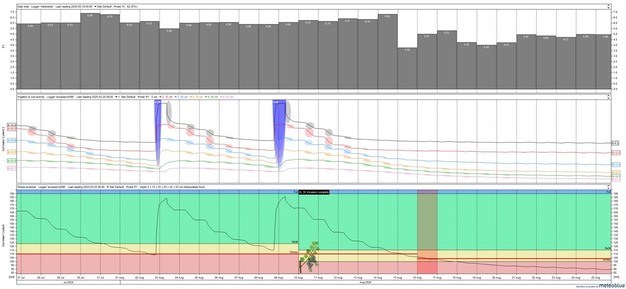

In this regard, it is important to mention the important role of the installation point in managing irrigation across the entire sector. Thanks to more targeted interventions that are no longer based on fixed schedules or empirical evaluations, growers immediately noticed a 10% reduction in irrigation volumes and a 30% reduction in fertilization. Furthermore, growers identified the total volumetric content panel as a reference graph on IrriMAX Live. This is because the graph clearly shows total water content patterns and helps determine when to start or stop irrigating, thanks to the irrigation management lines.

© Sentek Srl © Sentek Srl |  © Sentek Srl © Sentek Srl |

Drill & Drop Installation

Thanks to a recent software update, stress and irrigation intervention thresholds can now be set with greater accuracy than ever before. Using Granier-type Sap Flow sensors (Fig. 4) further improves the robustness and precision of Sentek's stress detection model. These sensors continuously measure sap flow to provide a direct estimate of the plants' transpiration rate. This data serves as an objective reference for validating IrriMAX's ability to accurately detect water stress conditions. The red lines in the final graph represent the stress functions that the software automatically identifies by comparing CWU and ET₀.

© Sentek SrlThe IrriMAX Live interface displays graphs of ET₀ and VWC per layer, as well as total VWC, from top to bottom

© Sentek SrlThe IrriMAX Live interface displays graphs of ET₀ and VWC per layer, as well as total VWC, from top to bottom

Whenever the soil water content displayed in IrriMAX dropped below the optimal threshold, the Sap Flow data clearly showed a reduction in transpiration, confirming the onset of physiological stress.

At the same time, daily and seasonal variations in trunk diameter could be monitored with the use of dendrometers. The reliability of the suggested intervention thresholds was further reinforced by the occurrence of more pronounced contraction signals during stress conditions, as identified by the software.

The analysis included spot measurements of leaf water potential, which were carried out using a Scholander pressure chamber. These measurements provided a key physiological reference for calibrating and interpreting the continuous sensor data and the IrriMAX display.

© Sentek Srl © Sentek Srl |  © Sentek Srl © Sentek Srl |

Sapflow probes and dendrometers

The meticulous and professional research conducted by the AgrHySMo group and Professor Rallo provided additional information for the scientific validation of Sentek technology. The accuracy of the Sentek Drill & Drop probes was confirmed through the integration of instruments used to measure variables such as sap flow, trunk diameter changes, and leaf water potential. These results lay the groundwork for winegrowers and others who doubt the technology's reliability and are exploring monitoring and decision support systems.

For more information:

Plasson Italia

Paolo Antini

Sentek Regional Manager Europe

[email protected]

Tommaso Cesaretti

Sentek Business Development and Training

[email protected]