The microbial risks inside a vertical farm vary from one zone to another. Powdery mildew in propagation rooms and Listeria in packhouses present very different challenges, yet both can compromise crops and operations. AirROS by Sage Industrial offers a dry, continuous disinfection system engineered to operate across all farm zones, from propagation to postharvest. The company says its systems are designed to sanitize air and surfaces across all stages of production.

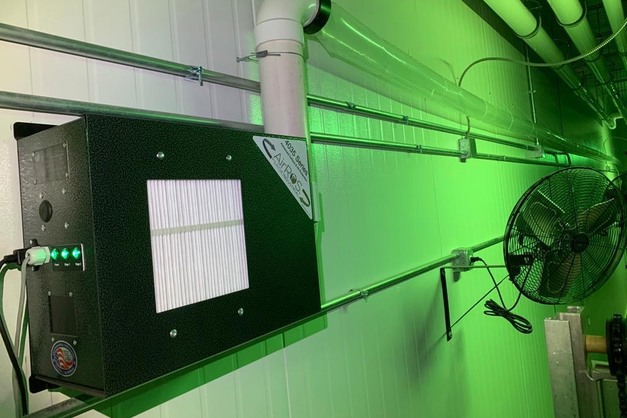

"In active production areas such as vertical grow rooms, greenhouses, or propagation zones, our systems run continuously to reduce and control airborne and surface pathogens," the company explains. "During periods of high humidity, when risks are highest, AirROS helps maintain clean airflow and lower microbial loads without constant chemical applications."

In postharvest environments, the focus shifts to spoilage prevention. "Packing, cooling, and storage areas benefit from 24/7 protection against organisms like Botrytis. By keeping these environments sanitized, AirROS extends shelf life and helps maintain quality standards without leaving residues." © AirROS by Sage Industrial

© AirROS by Sage Industrial

Targeting pathogens across the production flow

The system is built to control a wide range of organisms that appear in different farm environments. "Powdery mildew, Botrytis, Aspergillus, Fusarium, and Alternaria are common in growing zones. In postharvest spaces the greater risks are bacteria, yeast, and foodborne pathogens such as E. coli, Salmonella, and Listeria."

According to AirROS, treating both the air and the surfaces that pathogens settle on provides a more consistent layer of protection. "We are not limited to ducted air. Our system creates an active oxidation zone in the ambient environment where pathogens actually spread and land."

A controlled blend of reactive oxygen species

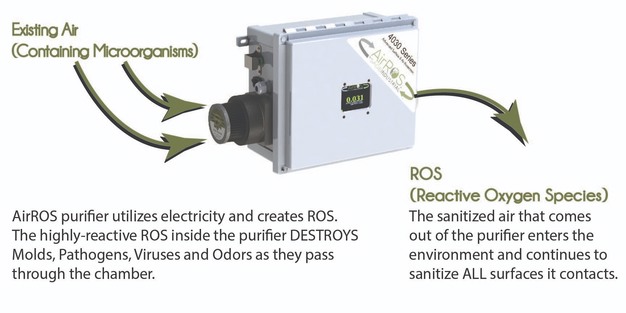

AirROS emphasizes that its method is distinct from conventional ozone, UV, or fogging systems. "Our technology creates a blend of seven reactive oxygen species, not just ozone." The company says these include atomic oxygen, hydroxyl radicals, singlet oxygen, superoxide, peroxynitrite, dry hydrogen peroxide, and trioxidane.

This is a two-stage process. "The first stage generates short-lived species in a high-energy chamber. The second stage diffuses longer-lived molecules such as hydrogen peroxide and ozone into the room. The result is dry, residue-free sanitation that is continuous and safe for people and plants." © AirROS by Sage Industrial

© AirROS by Sage Industrial

Safe use in occupied grow zones

Safety remains central to the system's design. "AirROS maintains ultra-low ozone levels, between 20 and 30 parts per billion. This is well below OSHA's eight-hour limit of 100 parts per billion. It is safe for workers, for live cannabis plants, and for edible produce."

Because there is no fogging, residue, or plant damage, the system can operate without interrupting farm activity. "Unlike UV or peroxide fogging, there is no need to vacate the room. Our devices are used in fruit packing houses and meat facilities twenty-four hours a day."

Integration with facility automation

Installation is designed to be simple. "Our units plug into standard outlets and draw very little power. Most require under 1.5 amps, and larger units draw up to 3.5 amps."

Commercial growers have already linked AirROS systems to automation platforms. "AirROS can be integrated into GrowLink, Argus, or custom building management systems. With IoT controllers and smart relays, farms can set zone-specific schedules, adjust ROS levels by crop stage, and link the system to temperature or humidity alerts." The Titan model is also equipped for Modbus integration.

Supporting compliance and certification

The company sees increasing demand from farms working toward third-party certification. "AirROS contributes directly to compliance under GlobalG.A.P., PrimusGFS, FSMA, and USDA Organic. Residue-free disinfection and OSHA-compliant exposure levels give auditors confidence that sanitation protocols are in place."

By reducing reliance on chemical disinfectants, farms can align their operations with both regulatory expectations and consumer demand for clean food production. "We help growers meet sanitation SOPs and environmental monitoring requirements while maintaining continuous protection." © AirROS by Sage Industrial

© AirROS by Sage Industrial

Product development and upgrades

The company has introduced new models and features in response to customer needs. "Our modular Titan system is designed for high-volume coverage with three to six modules per zone. We have added IoT options for data logging and remote control, as well as mobile cart units that can be rolled into drying or packaging areas."

Diffuser design has also been updated to improve distribution. "We engineered new smart diffusers to handle challenging airflow conditions, and we added light indicators to provide clear status and maintenance feedback."

Facility-wide protection without disruption

For vertical farms facing pressure to improve compliance, minimize losses, and maintain efficient operations, AirROS positions itself as a system that can run continuously across the entire facility. "We are not a single-room solution. AirROS is designed to protect every zone of the farm without disruption."

For more information:

For more information:

AirROS by SAGE

Hector Guzman, Marketing

[email protected]

www.airrosbysage.com