Vanmark has expanded the use of its hydrocutting machines with the introduction of curly fry spirals. The company's Helix Hydrocutting System uses water, powered by a pump loop, to accelerate through a fixed array of stainless-steel blades. The system is designed as a high-volume cutting solution that can be configured to suit different processing capacities and facility layouts.

© Vanmark

© Vanmark

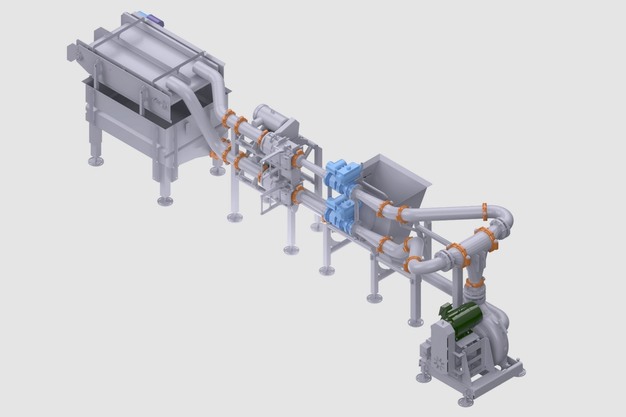

According to Vanmark, the Helix Hydrocutting System can process up to 5,000 pounds (2,268 kilograms) per hour per cutter, with yields of up to 92% sellable product. The equipment can be configured with two or more than twelve cutters, which can be stacked to reduce the footprint and mounted either on a cutting deck or directly to the floor.

The complete system is supplied with a pump, distributor, cutters, and a dewatering conveyor. Maintenance has been designed to be simplified, with a patent-pending blade system that can be changed without tools. In addition, the company offers an annual rebuild service carried out by Vanmark technicians.

© Vanmark

© Vanmark

The addition of curly fry spirals allows processors to enter new product segments while maintaining throughput and efficiency levels associated with hydrocutting technology.

For more information:

Vanmark

Tel: +1 208-362-5588

[email protected]

www.vanmark.com